Machine room insulation cotton is generally used for top insulation, wall insulation and ground insulation, wall insulation cotton is thicker than the top and ground, the top and ground are usually 10MM thick and 20MM thick, some machine rooms also have fire prevention requirements, to warm cotton fire level can reach B1. For example: 100 square machine room: 100 square heat preservation on the top (available or not according to the room design requirements), 100 square heat preservation on the ground (generally used), wall (generally with light steel keel inside the partition will place sound insulation cotton), the amount of wall insulation cotton is calculated according to the area of the wall, the original wall wall does not need latex paint.

一、Importance of room insulation

The technical problems such as winter insulation, summer insulation and dew prevention in computer room are important factors for the design of computer room. Especially in summer, the outdoor temperature is higher, and the relative humidity of the air is also high. Due to the large temperature difference between the inside and outside of the computer room, improper insulation treatment of the computer room will cause condensation at two adjacent interfaces of the computer room area. More importantly, the condensation of the lower ceiling structure surface will damage adjacent facilities and affect the work. At the same time, it will increase the load of air conditioning in the room area, causing a waste of energy. In winter, because the temperature/humidity of the machine room is constant, the relative humidity is higher than outdoor at this time. The inside facade wall and the skyline floor of the machine room produce condensation, which causes the machine room to be wet, causing damage to the wall facade and the skyline floor structure, and affecting the cleanliness of the machine room.

Evaporation of condensated water at the interface causes humidity to increase in the air in local areas and damage to components and cable plug-ins of computers and microelectronic devices. Therefore, in order to save energy and reduce operating costs in the future, according to the above analysis, computer room adjacent interface condensation should start from it and take appropriate measures to control plane, facade insulation and heat loss.

二、Thermal and moisture-resistant treatment scheme for machine room

(1)Pipes unrelated to the machine room area must not pass through the main room. Inevitably, dew proof and heat preservation should be done. Zinc-plated steel pipe threaded connection is used for water pipes. Tight seams are ensured and tested by pressure test.

(2)There are dikes around the air conditioner and a leak alarm system around the precision air conditioner and under the water pipe where water may be produced.

(3)When using the active floor air supply method, the floor should take insulation measures.

The insulation layer underneath the floor keeps the room at a constant temperature without condensating the roof of the next floor, and the dust on the floor is not blown into the machine by the wind.

三、Cautions for insulation of machine room floor:

1、Press 600*600 intersection to fix the electrostatic floor foot position after the whole machine room elastic line

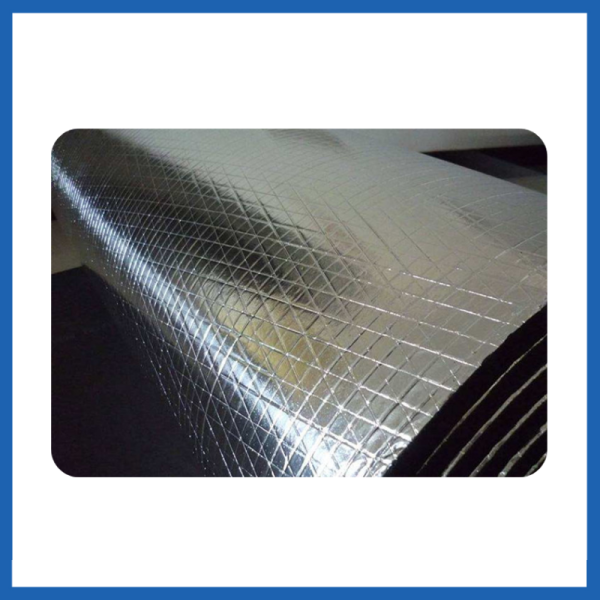

2、Large sheets of insulated roll material, cross-cut opening of floor foot cut, each piece of insulated tape connected

3、Place an electrostatic floor and adjust the level synchronously.

The types of anti-static floor are: all-steel anti-static floor, ceramic anti-static floor, calcium silicate anti-static floor, calcium sulfate anti-static floor, aluminum alloy anti-static floor, ventilation anti-static floor, PVC anti-static floor, ceramic anti-static tiles, etc. The application range is wider. Different types of anti-static floor are used in different anti-static places.